- 您現在的位置:買賣IC網 > PDF目錄373919 > AD7840JN (ANALOG DEVICES INC) LC2MOS Complete 14-Bit DAC PDF資料下載

參數資料

| 型號: | AD7840JN |

| 廠商: | ANALOG DEVICES INC |

| 元件分類: | DAC |

| 英文描述: | LC2MOS Complete 14-Bit DAC |

| 中文描述: | SERIAL, PARALLEL, WORD INPUT LOADING, 2.5 us SETTLING TIME, 14-BIT DAC, PDIP24 |

| 封裝: | PLASTIC, DIP-24 |

| 文件頁數: | 12/16頁 |

| 文件大小: | 337K |

| 代理商: | AD7840JN |

AD7840

REV. B

–12–

AD7840–TMS32020 Serial Interface

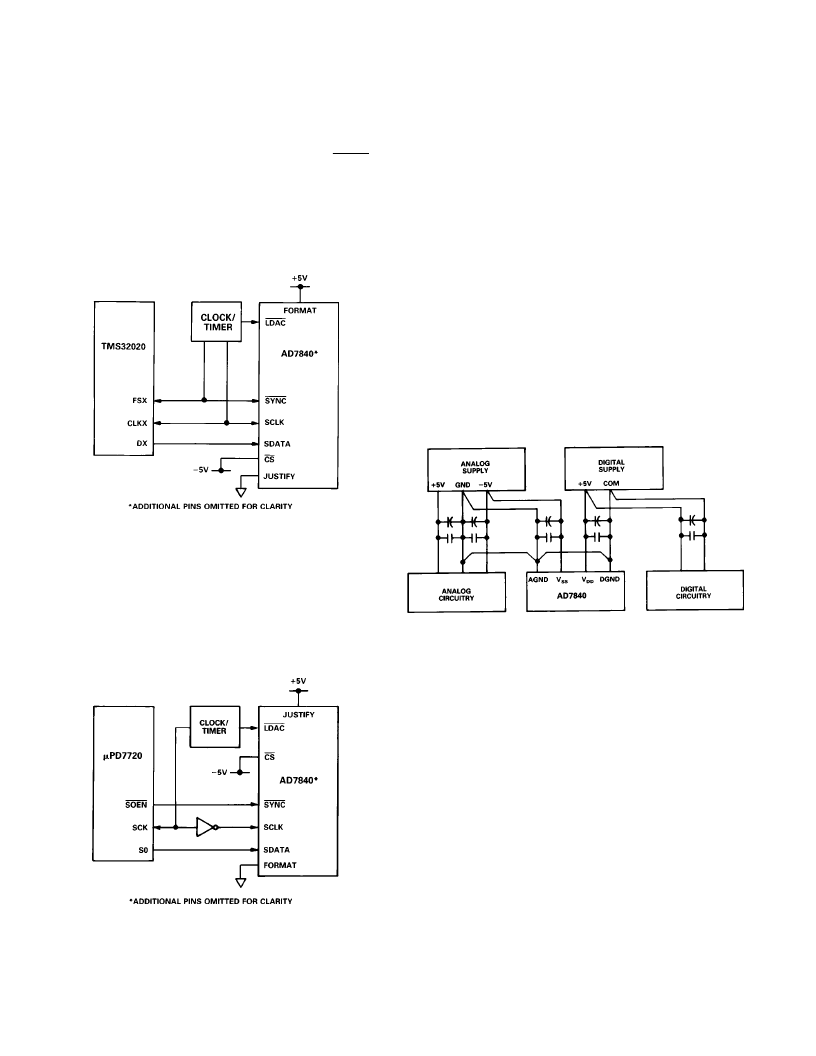

Figure 22 shows a serial interface between the AD7840 and the

T MS32020 DSP processor. In this interface, the CLK X and

FSX pin of the T MS32020 are generated from the clock/timer

circuitry. T he same clock/timer circuitry generates the

LDAC

signal of the AD7840 to synchronize the update of the output

with the serial transmission. T he FSX pin of the T MS32020

must be configured as an input.

Data from the T MS32020 is valid on the falling edge of CLK X .

Once again, the FORMAT pin of the AD7840 must be tied to

+5 V while the JUST IFY pin must be tied to DGND.

Figure 22. AD7840–TMS32020 Serial Interface

AD7840–NEC7720 Serial Interface

A serial interface between the AD7840 and the NEC7720 is

shown in Figure 23. T he serial clock must be inverted before

being applied to the AD7840 SCLK input because data from

the processor is valid on the rising edge of SCK .

T he NEC7720 is programmed for the LSB to be the first bit in

the serial data stream. T herefore, the AD7840 is set up with the

FORMAT pin tied to DGND and the JUST IFY pin tied to +5 V.

Figure 23. AD7840–NEC7720 Serial Interface

APPLY ING T HE AD7840

Good printed circuit board layout is as important as the overall

circuit design itself in achieving high speed converter perfor-

mance. T he AD7840 works on an LSB size of 366

μ

V. T here-

fore, the designer must be conscious of minimizing noise in both

the converter itself and in the surrounding circuitry. Switching

mode power supplies are not recommended as the switching

spikes can feed through to the on-chip amplifier. Other causes

of concern are ground loops and digital feedthrough from mi-

croprocessors. T hese are factors which influence any high per-

formance converter, and a proper PCB layout which minimizes

these effects is essential for best performance.

LAY OUT HINT S

Ensure that the layout for the printed circuit board has the digi-

tal and analog lines separated as much as possible. T ake care

not to run any digital track alongside an analog signal track. Es-

tablish a single point analog ground (star ground) separate from

the logic system ground. Place this star ground as close as pos-

sible to the AD7840 as shown in Figure 24. Connect all analog

grounds to this star ground and also connect the AD7840

DGND pin to this ground. Do not connect any other digital

grounds to this analog ground point.

Figure 24. Power Supply Grounding Practice

Low impedance analog and digital power supply common re-

turns are essential to low noise operation of high performance

converters. T herefore, the foil width for these tracks should be

kept as wide as possible. T he use of ground planes minimizes

impedance paths and also guards the analog circuitry from digi-

tal noise. T he circuit layouts of Figures 27 and 28 have both

analog and digital ground planes which are kept separated and

only joined at the star ground close to the AD7840.

NOISE

K eep the signal leads on the V

OUT

signal and the signal return

leads to AGND as short as possible to minimize noise coupling.

In applications where this is not possible, use a shielded cable

between the DAC output and its destination. Reduce the

ground circuit impedance as much as possible since any poten-

tial difference in grounds between the DAC and its destination

device appears as an error voltage in series with the DAC output.

相關PDF資料 |

PDF描述 |

|---|---|

| AD7840JP | LC2MOS Complete 14-Bit DAC |

| AD7840KN | LC2MOS Complete 14-Bit DAC |

| AD7840KP | LC2MOS Complete 14-Bit DAC |

| AD7840SQ | LC2MOS Complete 14-Bit DAC |

| AD7840 | LC2MOS Complete 14-Bit DAC |

相關代理商/技術參數 |

參數描述 |

|---|---|

| AD7840-JN | 制造商: 功能描述: 制造商:undefined 功能描述: |

| AD7840JNZ | 功能描述:IC DAC 14BIT LC2MOS LP 24-DIP RoHS:是 類別:集成電路 (IC) >> 數據采集 - 數模轉換器 系列:- 產品培訓模塊:Lead (SnPb) Finish for COTS Obsolescence Mitigation Program 標準包裝:50 系列:- 設置時間:4µs 位數:12 數據接口:串行 轉換器數目:2 電壓電源:單電源 功率耗散(最大):- 工作溫度:-40°C ~ 85°C 安裝類型:表面貼裝 封裝/外殼:8-TSSOP,8-MSOP(0.118",3.00mm 寬) 供應商設備封裝:8-uMAX 包裝:管件 輸出數目和類型:2 電壓,單極 采樣率(每秒):* 產品目錄頁面:1398 (CN2011-ZH PDF) |

| AD7840JNZ | 制造商:Analog Devices 功能描述:IC 14-BIT DAC |

| AD7840JP | 功能描述:IC DAC 14BIT LC2MOS VOUT 28PLCC RoHS:否 類別:集成電路 (IC) >> 數據采集 - 數模轉換器 系列:- 產品培訓模塊:Data Converter Fundamentals DAC Architectures 標準包裝:750 系列:- 設置時間:7µs 位數:16 數據接口:并聯 轉換器數目:1 電壓電源:雙 ± 功率耗散(最大):100mW 工作溫度:0°C ~ 70°C 安裝類型:表面貼裝 封裝/外殼:28-LCC(J 形引線) 供應商設備封裝:28-PLCC(11.51x11.51) 包裝:帶卷 (TR) 輸出數目和類型:1 電壓,單極;1 電壓,雙極 采樣率(每秒):143k |

| AD7840JP-REEL | 制造商:Rochester Electronics LLC 功能描述: 制造商:Analog Devices 功能描述: |

發布緊急采購,3分鐘左右您將得到回復。