- 您現在的位置:買賣IC網 > PDF目錄373931 > AD8041AN (ANALOG DEVICES INC) 160 MHz Rail-to-Rail Amplifier with Disable PDF資料下載

參數資料

| 型號: | AD8041AN |

| 廠商: | ANALOG DEVICES INC |

| 元件分類: | 運動控制電子 |

| 英文描述: | 160 MHz Rail-to-Rail Amplifier with Disable |

| 中文描述: | OP-AMP, 8000 uV OFFSET-MAX, PDIP8 |

| 封裝: | PLASTIC, DIP-8 |

| 文件頁數: | 14/16頁 |

| 文件大小: | 438K |

| 代理商: | AD8041AN |

REV. 0

–14–

AD8041

To test this, the differential gain and differential phase were

measured for the AD8041 while the supplies were varied. As the

lower supply is raised to approach the video signal, the first ef-

fect to be observed is that the sync tips become compressed be-

fore the differential gain and differential phase are adversely

affected. Thus, there must be adequate swing in the negative di-

rection to pass the sync tips without compression.

As the upper supply is lowered to approach the video, the differ-

ential gain and differential phase were not significantly adversely

affected until the difference between the peak video output and

the supply reached 0.6 V. Thus, the highest video level should

be kept at least 0.6 V below the positive supply rail.

Taking the above into account, it was found that the optimal

point to bias the noninverting input is at 2.2 V dc. Operating at

this point, the worst case differential gain is measured at 0.06%

and the worst case differential phase is 0.06

°

.

The ac coupling capacitors used in the circuit at first glance ap-

pear quite large. A composite video signal has a lower frequency

band edge of 30 Hz. The resistances at the various ac coupling

points—especially at the output—are quite small. In order to

minimize phase shifts and baseline tilt, the large value capacitors

are required. For video system performance that is not to be of

the highest quality, the value of these capacitors can be reduced

by a factor of up to five with only a slightly observable change in

the picture quality.

Sync Stripper

Some RGB monitor systems use only three cables total and

carry the synchronizing signals along with the Green (G) signal

on the same cable. The sync signals are pulses that go in the

negative direction from the blanking level of the G signal.

In some applications like prior to digitizing component video

signals with A/D converters, it is desirable to remove or strip the

sync portion from the G signal. Figure 43 is a schematic of a cir-

cuit using the AD8041 running on a single +5 V supply that

performs this function.

AD8041

R2

1k

10μF

0.1μF

0.8V

(2X V

BLANK

)

+5V

75

V

IN

75

75

(MONITOR)

R1

1k

7

6

3

2

4

GREEN W/SYNC

V

BLANK

+0.4

GROUND

GREEN W/OUT SYNC

GROUND

Figure 43. Single Supply Sync Stripper

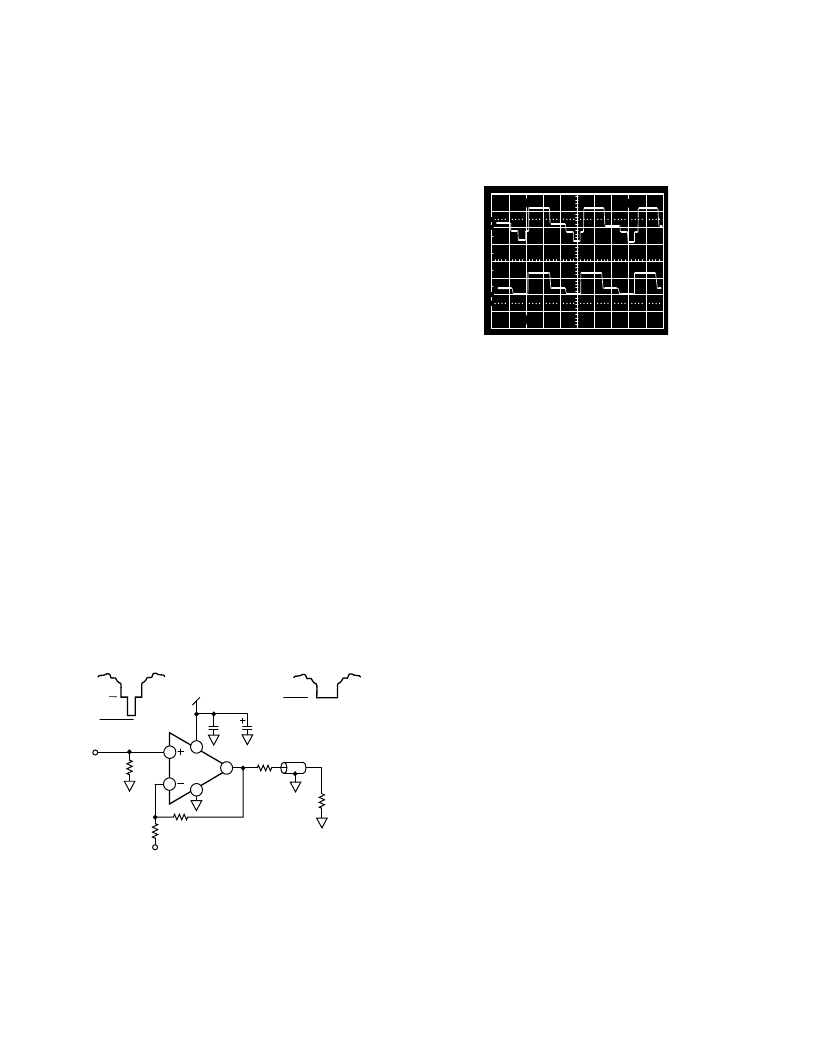

Referring to Figure 44, the Green plus sync signal is output

from an ADV7120, a single supply triple video DAC. Because

the DAC is single supply, the lowest level of the sync tip is at

ground or slightly above. The AD8041 is set for a gain of two to

compensate for the divide by two of the output terminations.

10

0%

100

90

10μs

500mV

500mV

Figure 44. Single Supply Sync Stripper

The reference voltage for R1 should be twice the dc blanking

level of the G signal. If the blanking level is at ground and the

sync tip is negative as in some dual supply systems, then R1 can

be tied to ground. In either case, the output will have the sync

removed and have the blanking level at ground.

Layout Considerations

The specified high speed performance of the AD8041 requires

careful attention to board layout and component selection.

Proper RF design techniques and low-pass parasitic component

selection are necessary.

The PCB should have a ground plane covering all unused por-

tions of the component side of the board to provide a low im-

pedance path. The ground plane should be removed from the

area near the input pins to reduce the stray capacitance.

Chip capacitors should be used for the supply bypassing (see

Figure 45). One end should be connected to the ground plane

and the other within 1/8 inch of each power pin. An additional

large (0.47

μ

F–10

μ

F) tantalum electrolytic capacitor should be

connected in parallel, but not necessarily so close, to supply cur-

rent for fast, large signal changes at the output.

The feedback resistor should be located close to the inverting

input pin in order to keep the stray capacitance at this node to a

minimum. Capacitance variations of less than 1 pF at the in-

verting input will significantly affect high speed performance.

Stripline design techniques should be used for long signal traces

(greater than about 1 inch). These should be designed with a

characteristic impedance of 50

or 75

and be properly termi-

nated at each end.

相關PDF資料 |

PDF描述 |

|---|---|

| AD8041AR | 160 MHz Rail-to-Rail Amplifier with Disable |

| AD8041ARZ-REEL | CMOS Low Cost, 10-Bit Multiplying DAC; Package: none available; No of Pins: 16; Temperature Range: Military |

| AD8042ARZ | Dual 160 MHz Rail-to-Rail Amplifier |

| AD8042ARZ-REEL | Dual 160 MHz Rail-to-Rail Amplifier |

| AD8042ARZ-REEL7 | Dual 160 MHz Rail-to-Rail Amplifier |

相關代理商/技術參數 |

參數描述 |

|---|---|

| AD8041ANZ | 功能描述:IC OPAMP VF R-R LP LDIST 8DIP RoHS:是 類別:集成電路 (IC) >> Linear - Amplifiers - Instrumentation 系列:- 標準包裝:1 系列:- 放大器類型:通用 電路數:4 輸出類型:滿擺幅 轉換速率:0.028 V/µs 增益帶寬積:105kHz -3db帶寬:- 電流 - 輸入偏壓:3nA 電壓 - 輸入偏移:100µV 電流 - 電源:3.3µA 電流 - 輸出 / 通道:12mA 電壓 - 電源,單路/雙路(±):2.7 V ~ 12 V,±1.35 V ~ 6 V 工作溫度:-40°C ~ 85°C 安裝類型:表面貼裝 封裝/外殼:14-TSSOP(0.173",4.40mm 寬) 供應商設備封裝:14-TSSOP 包裝:剪切帶 (CT) 其它名稱:OP481GRUZ-REELCT |

| AD8041ANZ | 制造商:Analog Devices 功能描述:IC AMP VOLTAGE FEEDBACK |

| AD8041AR | 功能描述:IC OPAMP VF R-R LP LDIST 8SOIC RoHS:否 類別:集成電路 (IC) >> Linear - Amplifiers - Instrumentation 系列:- 標準包裝:73 系列:Over-The-Top® 放大器類型:通用 電路數:4 輸出類型:滿擺幅 轉換速率:0.07 V/µs 增益帶寬積:200kHz -3db帶寬:- 電流 - 輸入偏壓:1nA 電壓 - 輸入偏移:285µV 電流 - 電源:50µA 電流 - 輸出 / 通道:25mA 電壓 - 電源,單路/雙路(±):2 V ~ 44 V,±1 V ~ 22 V 工作溫度:-40°C ~ 85°C 安裝類型:表面貼裝 封裝/外殼:16-WFDFN 裸露焊盤 供應商設備封裝:16-DFN-EP(5x3) 包裝:管件 |

| AD8041AR-EBZ | 功能描述:BOARD EVAL FOR AD8041AR RoHS:是 類別:編程器,開發系統 >> 評估板 - 運算放大器 系列:- 產品培訓模塊:Lead (SnPb) Finish for COTS Obsolescence Mitigation Program 標準包裝:1 系列:- |

| AD8041AR-REEL | 功能描述:IC OPAMP VF R-R LP LDIST 8SOIC RoHS:否 類別:集成電路 (IC) >> Linear - Amplifiers - Instrumentation 系列:- 標準包裝:50 系列:LinCMOS™ 放大器類型:通用 電路數:4 輸出類型:- 轉換速率:0.05 V/µs 增益帶寬積:110kHz -3db帶寬:- 電流 - 輸入偏壓:0.7pA 電壓 - 輸入偏移:210µV 電流 - 電源:57µA 電流 - 輸出 / 通道:30mA 電壓 - 電源,單路/雙路(±):3 V ~ 16 V,±1.5 V ~ 8 V 工作溫度:-40°C ~ 85°C 安裝類型:表面貼裝 封裝/外殼:14-SOIC(0.154",3.90mm 寬) 供應商設備封裝:14-SOIC 包裝:管件 產品目錄頁面:865 (CN2011-ZH PDF) 其它名稱:296-1834296-1834-5 |

發布緊急采購,3分鐘左右您將得到回復。