- 您現在的位置:買賣IC網 > PDF目錄371042 > MC68040V (Motorola, Inc.) 32-Bit Microprocessor(32位微處理器) PDF資料下載

參數資料

| 型號: | MC68040V |

| 廠商: | Motorola, Inc. |

| 英文描述: | 32-Bit Microprocessor(32位微處理器) |

| 中文描述: | 32位微處理器(32位微處理器) |

| 文件頁數: | 347/442頁 |

| 文件大小: | 2582K |

| 代理商: | MC68040V |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁第93頁第94頁第95頁第96頁第97頁第98頁第99頁第100頁第101頁第102頁第103頁第104頁第105頁第106頁第107頁第108頁第109頁第110頁第111頁第112頁第113頁第114頁第115頁第116頁第117頁第118頁第119頁第120頁第121頁第122頁第123頁第124頁第125頁第126頁第127頁第128頁第129頁第130頁第131頁第132頁第133頁第134頁第135頁第136頁第137頁第138頁第139頁第140頁第141頁第142頁第143頁第144頁第145頁第146頁第147頁第148頁第149頁第150頁第151頁第152頁第153頁第154頁第155頁第156頁第157頁第158頁第159頁第160頁第161頁第162頁第163頁第164頁第165頁第166頁第167頁第168頁第169頁第170頁第171頁第172頁第173頁第174頁第175頁第176頁第177頁第178頁第179頁第180頁第181頁第182頁第183頁第184頁第185頁第186頁第187頁第188頁第189頁第190頁第191頁第192頁第193頁第194頁第195頁第196頁第197頁第198頁第199頁第200頁第201頁第202頁第203頁第204頁第205頁第206頁第207頁第208頁第209頁第210頁第211頁第212頁第213頁第214頁第215頁第216頁第217頁第218頁第219頁第220頁第221頁第222頁第223頁第224頁第225頁第226頁第227頁第228頁第229頁第230頁第231頁第232頁第233頁第234頁第235頁第236頁第237頁第238頁第239頁第240頁第241頁第242頁第243頁第244頁第245頁第246頁第247頁第248頁第249頁第250頁第251頁第252頁第253頁第254頁第255頁第256頁第257頁第258頁第259頁第260頁第261頁第262頁第263頁第264頁第265頁第266頁第267頁第268頁第269頁第270頁第271頁第272頁第273頁第274頁第275頁第276頁第277頁第278頁第279頁第280頁第281頁第282頁第283頁第284頁第285頁第286頁第287頁第288頁第289頁第290頁第291頁第292頁第293頁第294頁第295頁第296頁第297頁第298頁第299頁第300頁第301頁第302頁第303頁第304頁第305頁第306頁第307頁第308頁第309頁第310頁第311頁第312頁第313頁第314頁第315頁第316頁第317頁第318頁第319頁第320頁第321頁第322頁第323頁第324頁第325頁第326頁第327頁第328頁第329頁第330頁第331頁第332頁第333頁第334頁第335頁第336頁第337頁第338頁第339頁第340頁第341頁第342頁第343頁第344頁第345頁第346頁當前第347頁第348頁第349頁第350頁第351頁第352頁第353頁第354頁第355頁第356頁第357頁第358頁第359頁第360頁第361頁第362頁第363頁第364頁第365頁第366頁第367頁第368頁第369頁第370頁第371頁第372頁第373頁第374頁第375頁第376頁第377頁第378頁第379頁第380頁第381頁第382頁第383頁第384頁第385頁第386頁第387頁第388頁第389頁第390頁第391頁第392頁第393頁第394頁第395頁第396頁第397頁第398頁第399頁第400頁第401頁第402頁第403頁第404頁第405頁第406頁第407頁第408頁第409頁第410頁第411頁第412頁第413頁第414頁第415頁第416頁第417頁第418頁第419頁第420頁第421頁第422頁第423頁第424頁第425頁第426頁第427頁第428頁第429頁第430頁第431頁第432頁第433頁第434頁第435頁第436頁第437頁第438頁第439頁第440頁第441頁第442頁

MOTOROLA

M68040 USER’S MANUAL

11-19

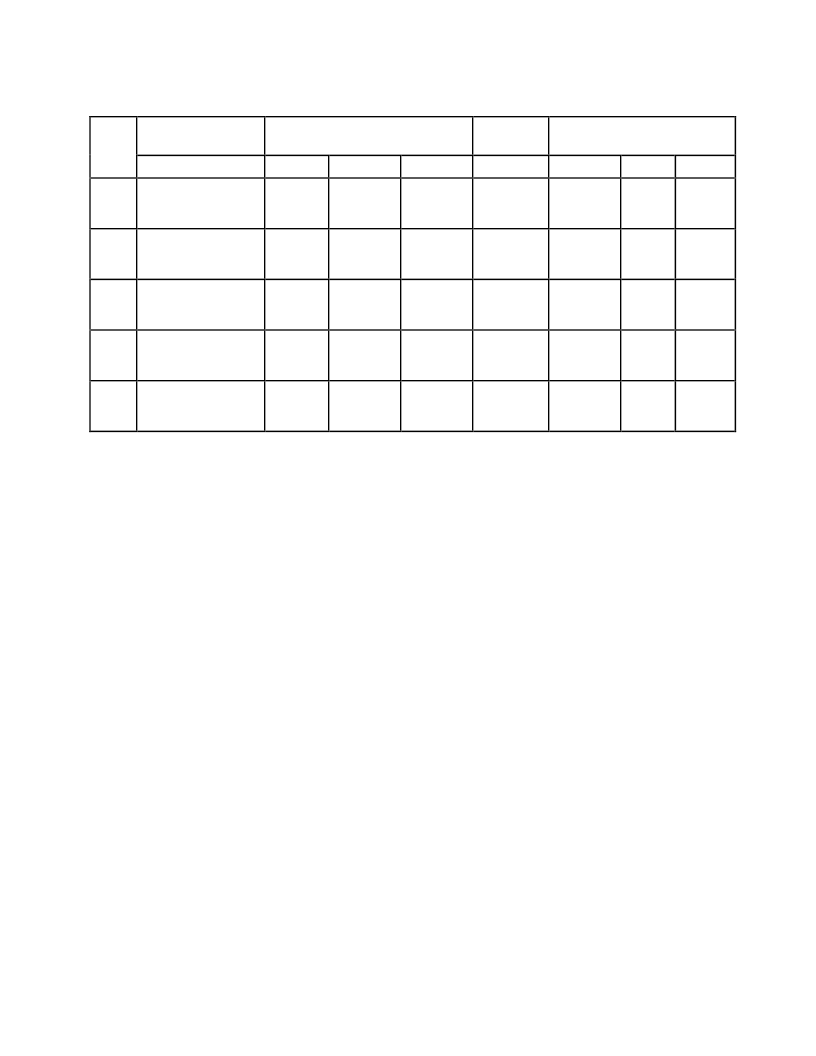

Table 11-4. Thermal Parameters with Forced Airflow and No Heat Sink

for the MC68LC040 and MC68EC040

Thermal Mgmt.

Technique

Defined Parameters

Measured

Calculated

MHz

Airflow Velocity

P

D

4 W

5 W

6.3W

T

J

θ

JC

θ

JA

θ

CA

T

C

T

A

20

25

33

100 LFM

110

°

C

3

°

C/W

12.7

°

C/W

9.7

°

C/W

98

°

C

95

°

C

91.1

°

C

98

°

C

95

°

C

91.1

°

C

98

°

C

95

°

C

91.1

°

C

98

°

C

95

°

C

91.1

°

C

98

°

C

95

°

C

91.1

°

C

59.2

°

C

46.5

°

C

29.9

°

C

66

°

C

55

°

C

40.70

°

C

70.4

°

C

60.5

°

C

47.63

°

C

72

°

C

62.5

°

C

50.15

°

C

72.8

°

C

63.5

°

C

51.41

°

C

20

25

33

250 LFM

4 W

5 W

6.3W

110

°

C

3

°

C/W

11

°

C/W

8

°

C/W

20

25

33

500 LFM

4 W

5 W

6.3W

110

°

C

3

°

C/W

9.9

°

C/W

6.9

°

C/W

20

25

33

750 LFM

4 W

5 W

6.3W

110

°

C

3

°

C/W

9.5

°

C/W

6.5

°

C/W

20

25

33

1000 LFM

4 W

5 W

6.3W

110

°

C

3

°

C/W

9.3

°

C/W

6.3

°

C/W

Reviewing the maximum ambient operating temperatures illustrates that using an all small

buffer configuration of the MC68040 with a relatively small amount of airflow (100 LFM)

achieves a 0–70

°

C ambient operating temperature. However, depending on the output

buffer configuration and available forced-air cooling, additional thermal management

techniques may be required.

11.9.3 With Heat Sink

The designer must consider many factors in choosing a heat sink: heat-sink size and

composition, method of attachment, and choice of a dry or wet (i.e., thermal grease)

connection. The following paragraphs discuss the relationship of these decisions to the

thermal performance of the design noticed during experimentation.

The heat-sink size is one of the most significant parameters to consider in the selection of

a heat sink. Obviously a larger heat sink provides better cooling. Under forced-air

conditions as low as 100 LFM, the difference between the

θ

CA

is very small (0.4

°

C/W or

less). This difference continues to decrease as the forced airflow increases.

The area of this example heat-sink base perimeter is 1.8"

×

1.8", with a height of 0.65".

The heat-sink used a pin-fin (i.e., bed-of-nails) design composed of aluminum alloy. Figure

11-32 illustrates the heat sink, which can be obtained through Thermalloy, Inc.

相關PDF資料 |

PDF描述 |

|---|---|

| MC68EC040 | 32-Bit Microprocessors.(32位微處理器) |

| MC68EC040V | 32-Bit Microprocessors.(32位微處理器) |

| MC68LC040 | 32-Bit Microprocessors.(32位微處理器) |

| MC68160BFB | ENHANCED ETHERNET INTERFACE TRANSCEIVER |

| MC68160 | ENHANCED ETHERNET INTERFACE TRANSCEIVER |

相關代理商/技術參數 |

參數描述 |

|---|---|

| MC6805S2 | 制造商:FREESCALE 制造商全稱:Freescale Semiconductor, Inc 功能描述:8-Bit Microcomputers |

| MC6805S2CL | 制造商:FREESCALE 制造商全稱:Freescale Semiconductor, Inc 功能描述:8-Bit Microcomputers |

| MC6805S2CP | 制造商:FREESCALE 制造商全稱:Freescale Semiconductor, Inc 功能描述:8-Bit Microcomputers |

| MC6805S2CS | 制造商:FREESCALE 制造商全稱:Freescale Semiconductor, Inc 功能描述:8-Bit Microcomputers |

| MC6805S2L | 制造商:FREESCALE 制造商全稱:Freescale Semiconductor, Inc 功能描述:8-Bit Microcomputers |

發布緊急采購,3分鐘左右您將得到回復。