- 您現在的位置:買賣IC網 > PDF目錄368072 > PME264NE6100MR30 (Electronic Theatre Controls, Inc.) EMI suppressor, class X2, metallized paper PDF資料下載

參數資料

| 型號: | PME264NE6100MR30 |

| 廠商: | Electronic Theatre Controls, Inc. |

| 英文描述: | EMI suppressor, class X2, metallized paper |

| 中文描述: | 電磁干擾抑制,類X2,金屬紙 |

| 文件頁數: | 1/2頁 |

| 文件大小: | 56K |

| 代理商: | PME264NE6100MR30 |

160

660 VAC 50/60 Hz

1500 VDC

(1600 VDC, + 50

°

C)

0.001

–

0.1 μF

± 20%

–

40 to +85

°

C

40/085/56/B

S, UL

≤

1.3 % at 1 kHz

≥

12000 M

Measured at 500 VDC after 60 s, +23

°

C

The 100% screening factory test is carried

out at 3000 VDC. The voltage level is

selected to meet the requirements in

applicable equipment standards.

PME264

EMI suppressor, class X2, metallized paper

0.001

–

0.1 μF, 660 VAC, +85

°

C

TYPICAL APPLICATIONS

CONSTRUCTION

TECHNICAL DATA

High AC and DC voltage applications,

such as

–

commutator capacitor in converters

–

high voltage DC-capacitor in TV sets

–

ignition circuits.

Multi-layer metallized paper. Encapsulated

and impregnated in self-extinguishing material

meeting the requirements of UL 94V-0.

Rated voltage

Capacitance range

Capacitance tolerance

Temperature range

Climatic category IEC

Approvals

Dissipation factor tan

δ

Insulation resistance

Test voltage between terminals

ENVIRONMENTAL TEST DATA

Vibration

IEC 60068-2-6

Test Fc

3 directions at 2 hour each,

10

–

500 Hz at 0.75 mm or 98 m/s

2

No open or short circuit

No visible damage

Bump

IEC 60068-2-29

Test Eb

4000 bumps at 390 m/s

2

No visible damage

No open or short circuit

Solderability

IEC 60068-2-20

Test Ta

Solder globule method

Wetting time

for d

≤

0.8 < 1 s

for d > 0.8 < 1.5 s

Active flammability

EN 132400

Passive flammability

IEC 60384-14 (1993)

EN 132400

Humidity

IEC 60068-2-3

Test Ca

+40

°

C and 90

–

95% R.H.

56 days

Self-extinguishing encapsulation.

High dU/dt capability.

Excellent self-healing properties.

Ensures long life even when subjected to

frequent overvoltages.

Good resistance to ionisation due to

impregnated dielectric.

The capacitors meet the most

stringent IEC humidity class, 56 days.

The impregnated paper ensures

excellent stability giving outstanding

reliability properties, especially in

applications having continuous

operation.

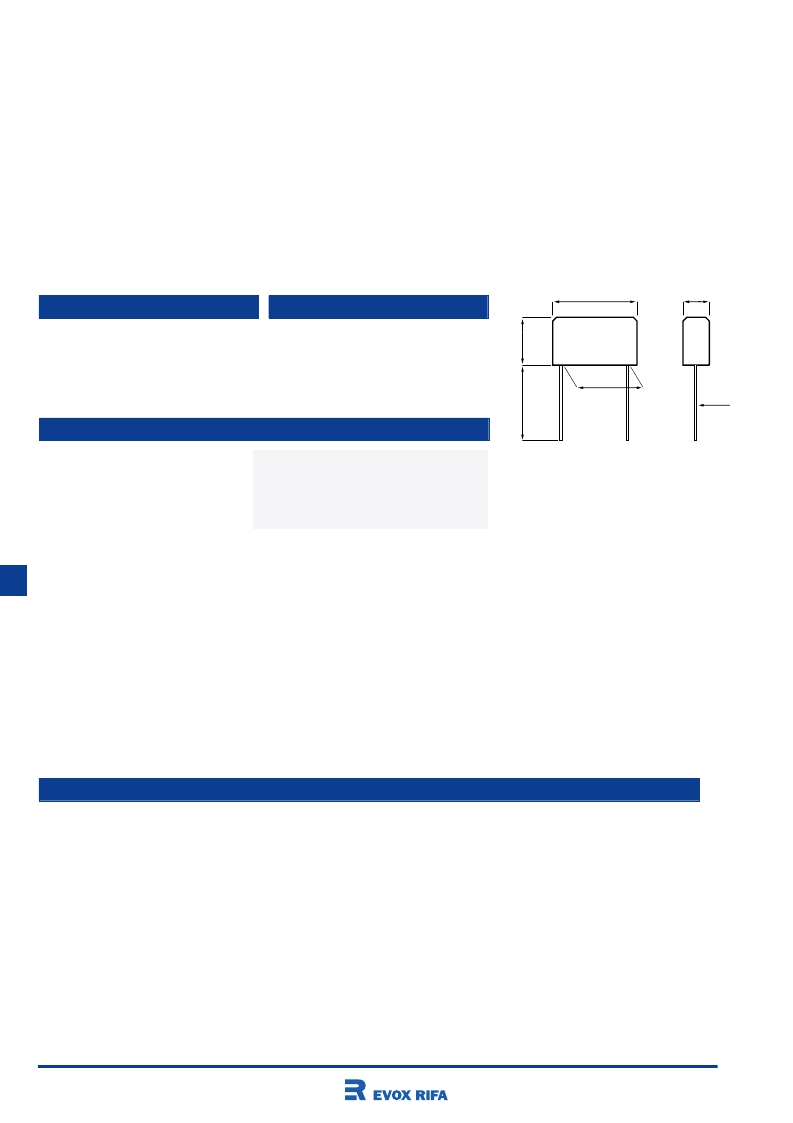

L

H

B

p

±

0.5

l

d

d =0.8 for p = 15.2 and 20.3

1.0 for p = 25.4

l = standard: 30 +5/-0 mm

option: short leads, tolerance +0/-1 mm

(standard 6 mm, code R06)

Other lead lengths on request

相關PDF資料 |

PDF描述 |

|---|---|

| PME271E547MR30 | EMI suppressor, classes X1 and X2, metallized paper |

| PME271E | EMI suppressor, classes X1 and X2, metallized paper |

| PME271E510MR30 | EMI suppressor, classes X1 and X2, metallized paper |

| PME271E515MR30 | EMI suppressor, classes X1 and X2, metallized paper |

| PME271E522MR30 | EMI suppressor, classes X1 and X2, metallized paper |

相關代理商/技術參數 |

參數描述 |

|---|---|

| PME265MB515M | 制造商:RIF 功能描述:RF315X250VAC .55LS RIFA N10H3A |

| PME265MB522M | 制造商:n/a 功能描述:RF222X250 .6 LS 20% RIFA'94 |

| PME265MB522MR06 | 制造商:RIF 功能描述:RF322X250 RIFA S8J5A |

| PME265MC547M | 制造商:RIF 功能描述:RF347X250VAC-20mmLS RIFA S8J3B |

| PME271610 | 制造商:RIF 功能描述:RF315X250VAC .55LS RIFA N10H3A |

發布緊急采購,3分鐘左右您將得到回復。