- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄374019 > ADP3167JR (ANALOG DEVICES INC) 5-Bit Programmable 2-Phase Synchronous Buck Controller PDF資料下載

參數(shù)資料

| 型號: | ADP3167JR |

| 廠商: | ANALOG DEVICES INC |

| 元件分類: | 穩(wěn)壓器 |

| 英文描述: | 5-Bit Programmable 2-Phase Synchronous Buck Controller |

| 中文描述: | DUAL SWITCHING CONTROLLER, 2000 kHz SWITCHING FREQ-MAX, PDSO16 |

| 封裝: | SOIC-16 |

| 文件頁數(shù): | 8/16頁 |

| 文件大小: | 292K |

| 代理商: | ADP3167JR |

REV. B

–8–

ADP3160/ADP3167

C

T

Selection—Choosing the Clock Frequency

The ADP3160 and ADP3167 use a fixed-frequency control archi-

tecture. The frequency is set by an external timing capacitor, C

T

.

The value of C

T

for a given clock frequency can be selected using

the graph in Figure 2.

The clock frequency determines the switching frequency, which

relates directly to switching losses and the sizes of the inductors

and input and output capacitors. A clock frequency of 400 kHz

sets the switching frequency of each phase, f

SW

, to 200 kHz, which

represents a practical trade-off between the switching losses and

the sizes of the output filter components. From Figure 2, for 400 kHz

the required timing capacitor value is 150 pF. For good frequency

stability and initial accuracy, it is recommended to use a capacitor

with a low temperature coefficient and tight tolerance, e.g., an

MLC capacitor with NPO dielectric and with 5% or less tolerance.

Inductance Selection

The choice of inductance determines the ripple current in the

inductor. Less inductance leads to more ripple current, which

increases the output ripple voltage and the conduction losses in

the MOSFETs, but allows using smaller size inductors and, for

a specified peak-to-peak transient deviation, output capacitors

with less total capacitance. Conversely, a higher inductance

means lower ripple current and reduced conduction losses,

but requires larger size inductors and more output capacitance

for the same peak-to-peak transient deviation. In a 2-phase

converter a practical value for the peak-to-peak inductor ripple

current is under 50% of the dc current in the same inductor.

A choice of 46% for this particular design example yields a total

peak-to-peak output ripple current of 23% of the total dc output

current. The following equation shows the relationship between

the inductance, oscillator frequency, peak-to-peak ripple current

in an inductor, and input and output voltages.

L

V

(

V

V

V

f

I

IN

AVG

¥

AVG

IN

SW

L RIPPLE

(

=

¥

¥

–

)

)

(1)

For 12.5 A peak-to-peak ripple current, which corresponds to

just under 50% of the 26.7 A full-load dc current in an induc-

tor, Equation 1 yields an inductance of:

¥

¥

/

12

400

2 12 5

A 600 nH inductor can be used, which gives a calculated ripple

current of 12.2 A at no load. The inductor should not saturate

at the peak current of 32.8 A and should be able to handle the

sum of the power dissipation caused by the average current of

26.7 A in the winding and the core loss.

The output ripple current is smaller than the inductor ripple

current due to the two phases partially canceling. This can be

calculated as follows:

¥

¥

¥

12

600

400

Designing an Inductor

Once the inductance is known, the next step is either to design

an inductor or find a standard inductor that comes as close as

possible to meeting the overall design goals. The first decision in

designing the inductor is to choose the core material. There are

several possibilities for providing low core loss at high frequen-

cies. Two examples are the powder cores (e.g., Kool-M

m

from

Magnetics) and the gapped soft ferrite cores (e.g., 3F3 or 3F4

from Philips). Low-frequency powdered iron cores should be

avoided due to their high core loss, especially when the inductor

value is relatively low and the ripple current is high.

L

V

V

V

A

V

kHz

nH

=

=

(

–1 635

)

.

.

12

1 635

565

I

V

V

(

V

V

12

(

L

2 1 635

–

f

V

V

nH

V

V

kHz

A

O

AVG

IN

AVG

IN

OSC

.

D

=

¥

¥

=

¥

=

2

2

2 1 635

9 9

.

–

)

.

)

(2)

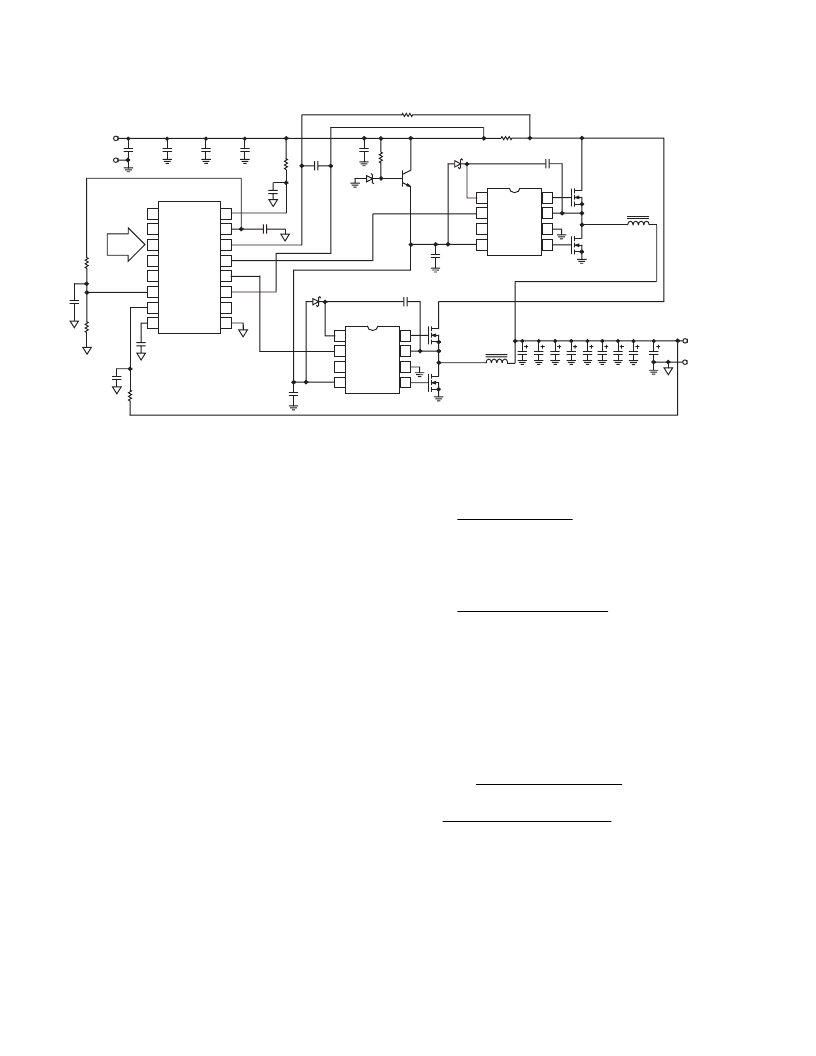

1

2

3

4

8

7

6

5

BST

IN

NC

VCC

DRVH

SW

PGND

DRVL

U2

ADP3414

U1

ADP3160

C23

C15C16 C17C18C19

270 F 4

OS-CON 16V

V

CC(CORE)

1.1V – 1.85V

53.4A

V

CC(CORE)

RTN

Q3

FDB7030L

D1

MBR052LTI

Q5

2N3904

L2

600nH

L1

600nH

Q1

FDB7030L

Q2

FDB8030L

C10

1 F

D2

MBR052LTI

C5

1 F

Z1

ZMM5236BCT

R5

2.4k

C25 1nF

C4

4.7 F

R6

10

C23

15nF

C14

C13

C12

C11

V

IN

12V

V

IN

RTN

C26

4.7 F

R

A

26.1k

C6

1 F

C9

1 F

R7

20

R4

4m

R

B

11.0k

C2

100pF

C1

150pF

R1

1k

Q4

FDB8030L

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

VID4

VID3

VID2

VID1

VID0

COMP

FB

CT

VCC

REF

CS–

PWM1

PWM2

CS+

PWRGD

GND

1

2

3

4

8

7

6

5

BST

IN

NC

VCC

DRVH

SW

PGND

DRVL

U3

ADP3414

C

3.3nF

2200 F 9

RUBYCON MBZ 6.3V

13m ESR (EACH)

C20 C21

FROM

CPU

NC = NO CONNECT

C22

Figure 6. 53.4 A Intel CPU Supply Circuit, VRM 9.0 FMB Design

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| ADP3163JRU | 5-Bit Programmable 2-/3-Phase Synchronous Buck Controller |

| ADP3163 | 500-mA, 4.2-V Li-Ion Charger for Current-Limited App. w/Temp Sense in MSOP-8 8-MSOP-PowerPAD -40 to 85 |

| ADP3166 | 5-Bit Programmable 2-, 3-, 4-Phase Synchronous Buck Controller |

| ADP3166JRU-REEL | 5-Bit Programmable 2-, 3-, 4-Phase Synchronous Buck Controller |

| ADP3166JRU-REEL7 | 5-Bit Programmable 2-, 3-, 4-Phase Synchronous Buck Controller |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| ADP3167JR-REEL7 | 制造商:Rochester Electronics LLC 功能描述:5BIT PROG'BLE 2 PHASE SYNCRO BUCK CNTRLR - Tape and Reel |

| ADP3168 | 制造商:AD 制造商全稱:Analog Devices 功能描述:6-Bit, Programmable 2-, 3-, 4-Phase Synchronous Buck Controller |

| ADP3168JRU-REEL | 制造商:AD 制造商全稱:Analog Devices 功能描述:6-Bit, Programmable 2-, 3-, 4-Phase Synchronous Buck Controller |

| ADP3168JRU-REEL7 | 制造商:Rochester Electronics LLC 功能描述:4PHASE CNTRLR/INTEL VRM 10COMPLIANT CPU - Tape and Reel |

| ADP3168JRUZ-REEL | 制造商:Rochester Electronics LLC 功能描述:4PHASE CNTRLR/INTEL VRM 10COMPLIANT CPU - Tape and Reel |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。