- 您現(xiàn)在的位置:買賣IC網(wǎng) > PDF目錄376695 > DF7-5EP-3.96C (Hirose Electric USA, INC.) 3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TUV Listed) PDF資料下載

參數(shù)資料

| 型號: | DF7-5EP-3.96C |

| 廠商: | Hirose Electric USA, INC. |

| 英文描述: | 3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TUV Listed) |

| 中文描述: | 三點(diǎn)九六毫米間距微型連接器內(nèi)部電源(UL認(rèn)證,及C - UL和TUV認(rèn)證) |

| 文件頁數(shù): | 3/16頁 |

| 文件大小: | 666K |

| 代理商: | DF7-5EP-3.96C |

3

I

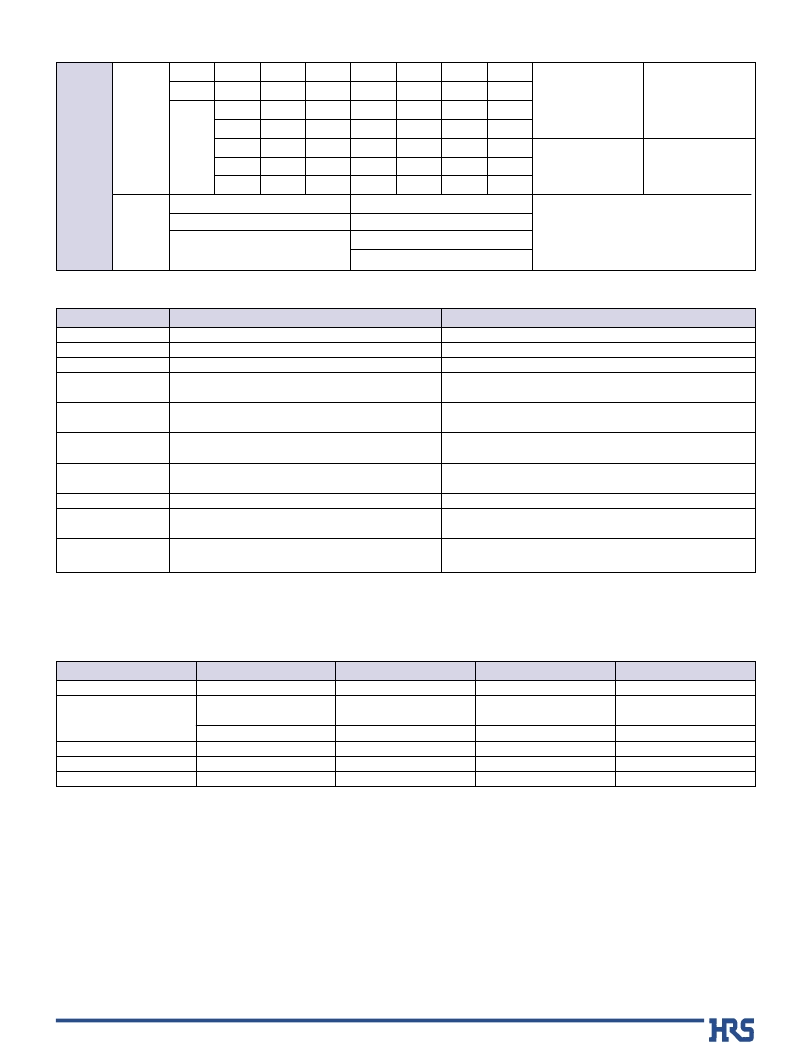

Materials

Product

Sockets

Headers

In-line plug

Retainer

Crimp contacts

Part

Insulator

Insulator

Contact

Insulator

Insulator

Contacts

Material

Polyamide

Polyamide

(Glass reinforced)

High conductivity copper alloy

Polyamide

Polyamide

High conductivity copper alloy

Finish

Color: White

Color: Beige (Single row)

Color: Grey (Double row)

Tin-lead plating (Note)

Color: White

Color: Black

Tin plating (Note)

Remarks

UL94V-0

UL94V-0

----------------

UL94V-0

UL94V-0

----------------

I

Product Specifications

Ratings

Current

rating

Row

No. of contacts

AWG16 AWG18 AWG20 AWG22 AWG24 AWG26

1

2~10

10A

7A

5A

4A

4A

3A

4

10A

9A

7A

6A

4A

3A

6

9A

8A

6A

5A

4A

3A

2

8

9A

8A

6A

5A

4A

3A

10

8A

7A

5A

4A

4A

3A

12

8A

7A

5A

4A

4A

3A

Operating temperature range

Operating humidity range

Storage temperature range

Storage humidity range

-10to 60 (Note 2)

40% to 70% (Note 2)

-35 to 85 (Note 1)

20% to 80%

Voltage

rating

Specificatoin

UL/C-UL

TüV

AC630V

AC/DC 600V

AC/DC 600V(7.92mm pitch)

AC/DC 300V (3.96mm pitch)

UL/C-UL/TüV

UL

C-UL

TüV

File No.and Recognition No

:E52653

:E52653

:R9750437

10 m ohms max. 20mV max., 1mA

500 V DC

1500 V AC for 1 minute

Measured with a steel pin of 0.64 x 1.2 ± 0.002 mm

Contact resistance of 20 m ohms max.

Frequency 10 to 55 Hz, single amplitude of 0.75 mm, 3 axis, 2

hours

Acceleration of 490 m/s

2

, 11 ms duration, sine half-wave

waveform, 3 cycles in each of the 3 axis.

Temperature 40

± 2

, 90% to 95% RH, 96 hours

(-55: 30 minutes

5 to 35: 5 minutes

85: 30 minutes

5

to 35: 5 minutes) for 5 cycles

Flow solder temperature 250, 10 seconds

Manual soldering: Soldering iron temperature 300, 3 seconds

Contact resistance(Initial value)

1000 M ohms min.

No flashover or Insulator breakdown

0.3N min., 4.5N max.

30 cycles

No momentary disconnections of 1 μs min.

No electrical discontinuity of 1 μs. min.

Contact resistance 20 m ohms max.

Contact resistance of 20 m ohms max.

No deformation of the insulator parts affecting

performance

1

1. Contact resistance

1

2.

Insulator resistance

1

3.

Withstanding voltage

1

4.

Insertion-Extraction force

(per contact)

1

5. Durability

(mating/unmating)

1

6. Vibration

1

7. Shock

1

8. Humidity

1

9. Temperature cycle

10. Resistance to

soldering heat

Item

Specification

Condition

Note 1: Includes temperature rise caused by the current flow.

Note 2: The term “storage” refers to products stored for long period of time prior to mounting and use. Operating Temperature Range

and Humidity range covers non- conducting condition of installed connectors in storage, shipment or during transportation.

Note: Hirose Electric's plating incorporates anti-whisking compounds.

相關(guān)PDF資料 |

PDF描述 |

|---|---|

| DF7-5EP-3.96DS | 3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TUV Listed) |

| DF7-5EP-3.96DSA | RES 10K0 SM 1/4W B 1206CS THNF T&R |

| DF7-5P-3.96C | RES, 10K, 1/8W, 0.1%, 1206 |

| DF7-5P-3.96DS | 3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TUV Listed) |

| DF7-5P-3.96DSA | 3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TUV Listed) |

相關(guān)代理商/技術(shù)參數(shù) |

參數(shù)描述 |

|---|---|

| DF75LA160 | 制造商:SANREX 制造商全稱:SanRex Corporation 功能描述:DIODE(THREE PHASES BRIDGE TYPE) |

| DF75LA80 | 制造商:SANREX 制造商全稱:SanRex Corporation 功能描述:DIODE(THREE PHASES BRIDGE TYPE) |

| DF75LB160 | 制造商:SANREX 制造商全稱:SanRex Corporation 功能描述:DIODE(THREE PHASES BRIDGE TYPE) |

| DF75LB80 | 制造商:SANREX 制造商全稱:SanRex Corporation 功能描述:DIODE(THREE PHASES BRIDGE TYPE) |

| DF7-5P-3.96C | 制造商:HRS 制造商全稱:HRS 功能描述:3.96 mm Pitch Miniature Connectors for Internal Power Supplies (UL,C-UL and TUV Listed) |

發(fā)布緊急采購,3分鐘左右您將得到回復(fù)。