- 您現在的位置:買賣IC網 > PDF目錄98283 > TPS54331DG4 (TEXAS INSTRUMENTS INC) 2 A SWITCHING REGULATOR, 684 kHz SWITCHING FREQ-MAX, PDSO8 PDF資料下載

參數資料

| 型號: | TPS54331DG4 |

| 廠商: | TEXAS INSTRUMENTS INC |

| 元件分類: | 穩壓器 |

| 英文描述: | 2 A SWITCHING REGULATOR, 684 kHz SWITCHING FREQ-MAX, PDSO8 |

| 封裝: | GREEN, PLASTIC, MS-012AA, SOIC-8 |

| 文件頁數: | 27/27頁 |

| 文件大小: | 794K |

| 代理商: | TPS54331DG4 |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁當前第27頁

www.ti.com

SLVS839C – JULY 2008 – REVISED MARCH 2010

CURRENT MODE COMPENSATION DESIGN

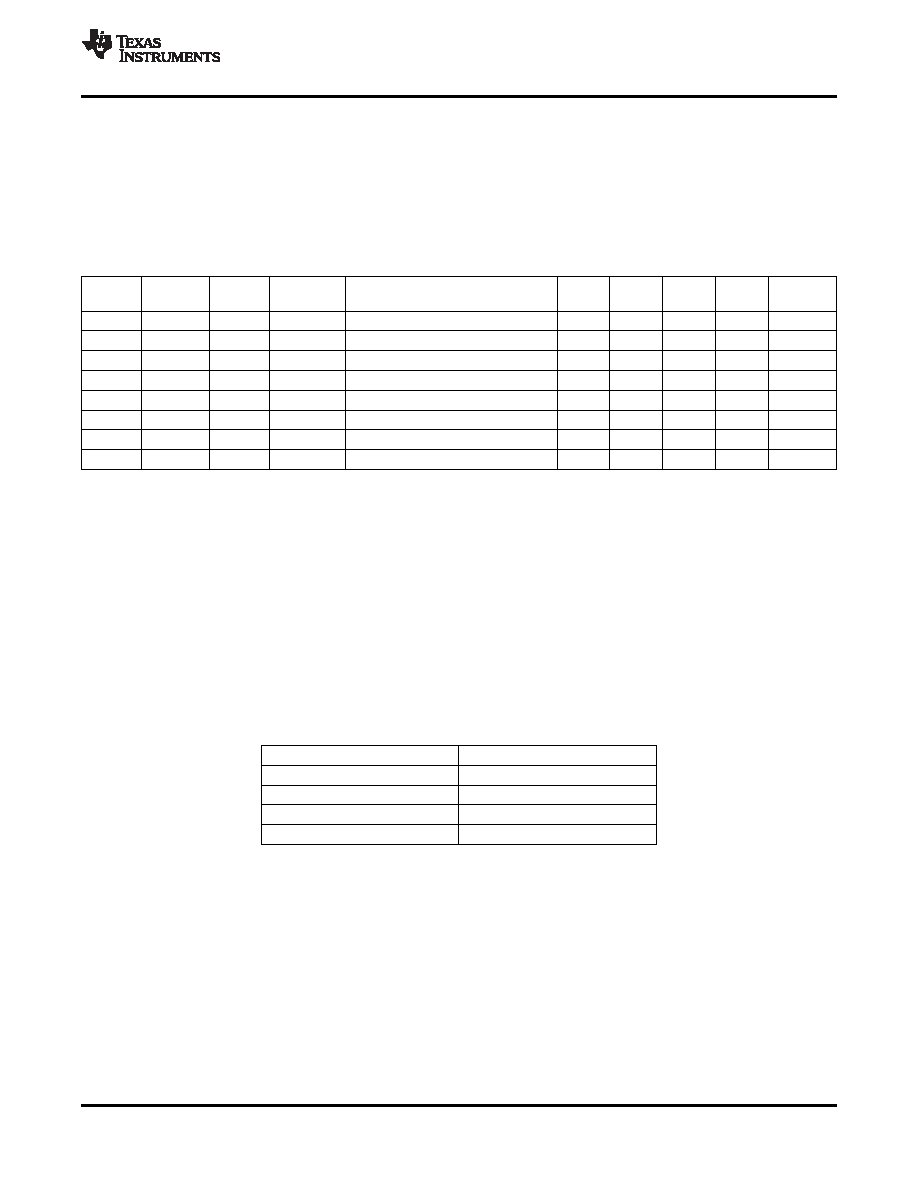

To simplify design efforts using the TPS54331, the typical designs for common applications are listed in Table 1.

For designs using ceramic output capacitors, proper derating of ceramic output capacitance is recommended

when doing the stability analysis. This is because the actual ceramic capacitance drops considerably from the

nominal value when the applied voltage increases. Advanced users may refer to the Step by Step Design

Procedure in the Application Information section for the detailed guidelines or use SwitcherPro Software tool

Table 1. Typical Designs (Referring to Simplified Schematic on page 1)

VIN

VOUT

Fsw

Lo

Co

RO1

RO2

C2

C1

R3

(V)

(kHz)

(mH)

(k

)

(k

)

(pF)

(k

)

12

5

570

6.8

Ceramic 33 mFx2

10

1.91

39

4700

49.9

12

3.3

570

6.8

Ceramic 47mFx2

10

3.24

47

1000

29.4

12

1.8

570

4.7

Ceramic 100 mF

10

8.06

68

5600

29.4

12

0.9

570

3.3

Ceramic 100 mFx2

10

80.6

56

5600

29.4

12

5

570

6.8

Aluminum 330 mF/160 m

10

1.91

68

120

29.4

12

3.3

570

6.8

Aluminum 470 mF/160 m

10

3.24

82

220

10

12

1.8

570

4.7

SP 100 mF/15 m

10

8.06

68

5600

29.4

12

0.9

570

3.3

SP 330 mF/12 m

10

80.6

100

1200

49.9

OVERCURRENT PROTECTION AND FREQUENCY SHIFT

The TPS54331 implements current mode control that uses the COMP pin voltage to turn off the high-side

MOSFET on a cycle by cycle basis. Every cycle the switch current and the COMP pin voltage are compared;

when the peak inductor current intersects the COMP pin voltage, the high-side switch is turned off. During

overcurrent conditions that pull the output voltage low, the error amplifier responds by driving the COMP pin high,

causing the switch current to increase. The COMP pin has a maximum clamp internally, which limit the output

current.

The TPS54331 provides robust protection during short circuits. There is potential for overcurrent runaway in the

output inductor during a short circuit at the output. The TPS54331 solves this issue by increasing the off time

during short circuit conditions by lowering the switching frequency. The switching frequency is divided by 8, 4, 2,

and 1 as the voltage ramps from 0 V to 0.8 V on VSENSE pin. The relationship between the switching frequency

and the VSENSE pin voltage is shown in Table 2.

Table 2. Switching Frequency Conditions

SWITCHING FREQUENCY

VSENSE PIN VOLTAGE

570 kHz

VSENSE

≥ 0.6 V

570 kHz / 2

0.6 V > VSENSE

≥ 0.4 V

570 kHz / 4

0.4 V > VSENSE

≥ 0.2 V

570 kHz / 8

0.2 V > VSENSE

OVERVOLTAGE TRANSIENT PROTECTION

The TPS54331 incorporates an overvoltage transient protection (OVTP) circuit to minimize output voltage

overshoot when recovering from output fault conditions or strong unload transients. The OVTP circuit includes an

overvoltage comparator to compare the VSENSE pin voltage and internal thresholds. When the VSENSE pin

voltage goes above 109% × Vref, the high-side MOSFET will be forced off. When the VSENSE pin voltage falls

below 107% × Vref, the high-side MOSFET will be enabled again.

THERMAL SHUTDOWN

The device implements an internal thermal shutdown to protect itself if the junction temperature exceeds 165°C.

The thermal shutdown forces the device to stop switching when the junction temperature exceeds the thermal

trip threshold. Once the die temperature decreases below 165°C, the device reinitiates the power up sequence.

Copyright 2008–2010, Texas Instruments Incorporated

9

Product Folder Link(s): TPS54331

相關PDF資料 |

PDF描述 |

|---|---|

| TPS54350MPWPREP | 7.2 A SWITCHING REGULATOR, 700 kHz SWITCHING FREQ-MAX, PDSO16 |

| TPS54372PWP | 3 A SWITCHING REGULATOR, 762 kHz SWITCHING FREQ-MAX, PDSO20 |

| TPS54418RTER | 6.4 A SWITCHING REGULATOR, 2000 kHz SWITCHING FREQ-MAX, PQCC16 |

| TPS54426PWP | 7.5 A SWITCHING REGULATOR, 700 kHz SWITCHING FREQ-MAX, PDSO14 |

| TPS54429PWP | 0.01 A SWITCHING REGULATOR, 700 kHz SWITCHING FREQ-MAX, PDSO14 |

相關代理商/技術參數 |

參數描述 |

|---|---|

| TPS54331DR | 功能描述:直流/直流開關轉換器 3A 28V In Step Down SWIFT DC/DC Cnvrtr RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開關頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數量:2 最大工作溫度:+ 85 C 安裝風格:SMD/SMT |

| TPS54331DRG4 | 功能描述:直流/直流開關轉換器 26V,3A DC-DC Converter RoHS:否 制造商:STMicroelectronics 最大輸入電壓:4.5 V 開關頻率:1.5 MHz 輸出電壓:4.6 V 輸出電流:250 mA 輸出端數量:2 最大工作溫度:+ 85 C 安裝風格:SMD/SMT |

| TPS54331DR-P | 制造商:Rochester Electronics LLC 功能描述: 制造商:Texas Instruments 功能描述: |

| TPS54331EVM-232 | 功能描述:電源管理IC開發工具 SWIFT Cnvrtr Eval Mod RoHS:否 制造商:Maxim Integrated 產品:Evaluation Kits 類型:Battery Management 工具用于評估:MAX17710GB 輸入電壓: 輸出電壓:1.8 V |

| TPS54331EVM-232 | 制造商:Texas Instruments 功能描述:DEVELOPMENT TOOL |

發布緊急采購,3分鐘左右您將得到回復。