- 您現在的位置:買賣IC網 > PDF目錄361044 > LMX9820A (National Semiconductor Corporation) Bluetooth Serial Port Module PDF資料下載

參數資料

| 型號: | LMX9820A |

| 廠商: | National Semiconductor Corporation |

| 英文描述: | Bluetooth Serial Port Module |

| 中文描述: | 藍牙串行端口模塊 |

| 文件頁數: | 39/44頁 |

| 文件大小: | 579K |

| 代理商: | LMX9820A |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁當前第39頁第40頁第41頁第42頁第43頁第44頁

Revision 1.0

39

www.national.com

L

15.0 Soldering

(Continued)

15.0 Soldering

The LMX9820A bumps are designed to melt as part of the

Surface Mount Assembly (SMA) process. The LMX9820A

is assembled with a high-temperature solder alloy to

ensure there are no re-reflow conditions imposed upon the

module when reflowed to a PCB with these typical low tem-

perature 60/40 (S = 183°C, L = 188°C), 62/36/2 (E =

179°C), or 63/37 (E = 183°C) solder alloys.

Where:

S: Solidus

– Denotes the points in a phase diagram representing

the temperature at which the solder composition be-

gins to melt during heating, or complete freezing dur-

ing cooling.

L: Liquidus

– Denotes the points in a phase diagram representing

the temperature at which the solder has molten com-

ponents. The temperature that melting starts at.

E: Eutectic

– Denotes solid to liquid without a plastic phase.

The low-temperature solder alloy will reflow with the solder

bump and provide the maximum allowable solder-joint reli-

ability.

Reflow at a peak of 215 --> 220°C (approximately 30 sec-

onds at peak). Do not to exceed 220°C, measured in close

proximity of the modules. to avoid any potential re-reflow

conditions.

Table 41 and Figure 27 on page 40 provide the soldering

details required to properly solder the LMX9820A to stan-

dard PCBs. The illustration serves only as a guide and

National is not liable if a selected profile does not work.

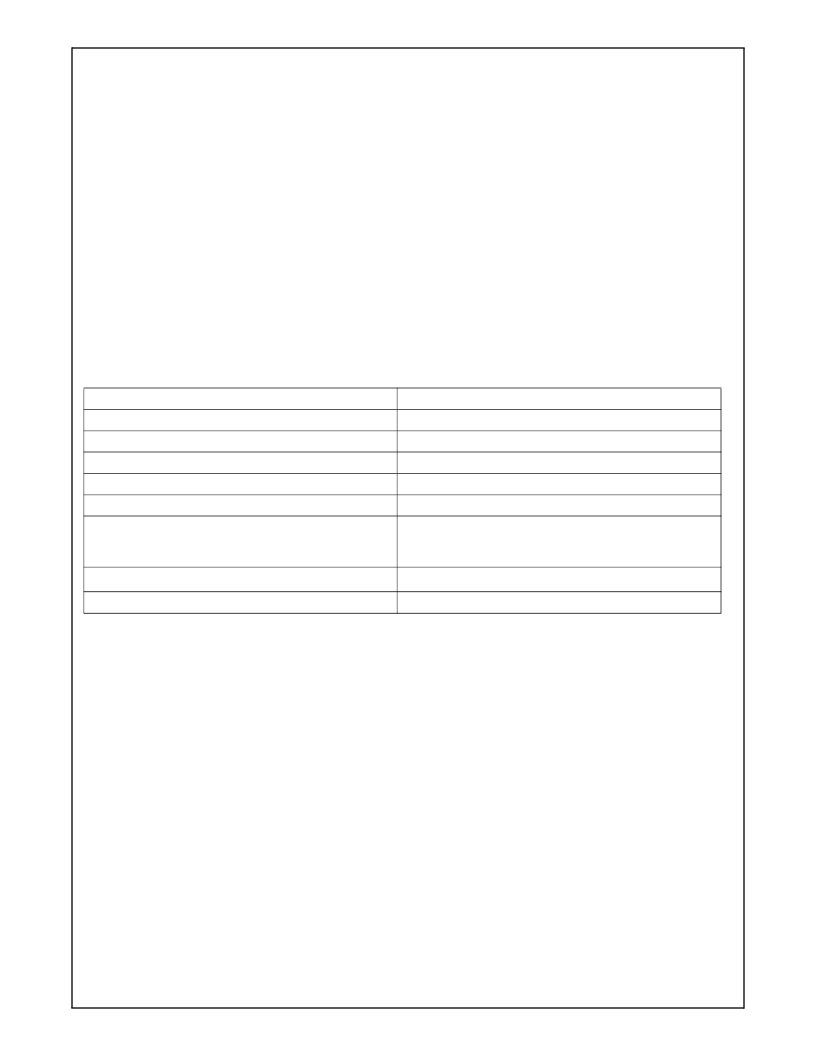

Table 41. Soldering Details

Parameter

Value

PCB Land Pad Diameter

24 mil

PCB Solder Mask Opening

30 mil

PCB Finish (HASL details)

63/37 (difference in thickness < 28 micron)

Stencil Aperture

28 mil

Stencil Thickness

5 mil

Solder Paste Used

Low temperature 60/40 (S = 183°C, L = 188°C),

62/36/2 (E = 179°C),

or 63/37 (E = 183°C) solder alloys

1

Flux Cleaning Process

No Clean Flux System

1

Reflow Profiles

See Figure 27 on page 40

1.

Typically defined by customer.

相關PDF資料 |

PDF描述 |

|---|---|

| LMX9820ASM | Bluetooth Serial Port Module |

| LMX9820 | Bluetooth Serial Port Module |

| LMX9820SB | Bluetooth Serial Port Module |

| LMX9820SBX | Bluetooth Serial Port Module |

| LP3882ESX-1.2 | 1.5A Fast-Response Ultra Low Dropout Linear |

相關代理商/技術參數 |

參數描述 |

|---|---|

| LMX9820ADEV | 制造商:Texas Instruments 功能描述:KIT DEV FOR LMX9820 |

| LMX9820ADONGLE/NOPB | 制造商:Texas Instruments 功能描述:KIT REF DESIGN FOR LMX9820 |

| LMX9820ASM | 制造商:Texas Instruments 功能描述:BLUETOOTH MODULE, SMD, 9820, FR4129 |

| LMX9820ASM/NOPB | 制造商:Texas Instruments 功能描述:IC MODULE BLUETOOTH 116-LTCC |

| LMX9820ASMX | 制造商:NSC 制造商全稱:National Semiconductor 功能描述:Bluetooth Serial Port Module |

發布緊急采購,3分鐘左右您將得到回復。