- 您現在的位置:買賣IC網 > PDF目錄16699 > AFE7222EVM (Texas Instruments)EVAL MODULE FOR AFE7222 PDF資料下載

參數資料

| 型號: | AFE7222EVM |

| 廠商: | Texas Instruments |

| 文件頁數: | 94/106頁 |

| 文件大小: | 0K |

| 描述: | EVAL MODULE FOR AFE7222 |

| 標準包裝: | 1 |

| 主要目的: | 接口,模擬前端(AFE) |

| 嵌入式: | 否 |

| 已用 IC / 零件: | AFE7222 |

| 已供物品: | 板 |

| 其它名稱: | 296-30300 AFE7222EVM-ND |

第1頁第2頁第3頁第4頁第5頁第6頁第7頁第8頁第9頁第10頁第11頁第12頁第13頁第14頁第15頁第16頁第17頁第18頁第19頁第20頁第21頁第22頁第23頁第24頁第25頁第26頁第27頁第28頁第29頁第30頁第31頁第32頁第33頁第34頁第35頁第36頁第37頁第38頁第39頁第40頁第41頁第42頁第43頁第44頁第45頁第46頁第47頁第48頁第49頁第50頁第51頁第52頁第53頁第54頁第55頁第56頁第57頁第58頁第59頁第60頁第61頁第62頁第63頁第64頁第65頁第66頁第67頁第68頁第69頁第70頁第71頁第72頁第73頁第74頁第75頁第76頁第77頁第78頁第79頁第80頁第81頁第82頁第83頁第84頁第85頁第86頁第87頁第88頁第89頁第90頁第91頁第92頁第93頁當前第94頁第95頁第96頁第97頁第98頁第99頁第100頁第101頁第102頁第103頁第104頁第105頁第106頁

CLKINP

CLKINN

Clock

Divider

%1,2,4

Clock

Divider

%1,2,4

PLL

X2,4

ADC_CLK

DAC_CLK

MUX

PLL_ENABLE

REG_SE_CLK

DIV_ADC<1:0>

DIV_DAC<1:0>

DCC

(Duty Cycle

Correction)

MUX

ENABLE_DCC

Single-

ended

Buffer

Single-

ended

Buffer

Differential

Buffer

SLOS711B – NOVEMBER 2011 – REVISED MARCH 2012

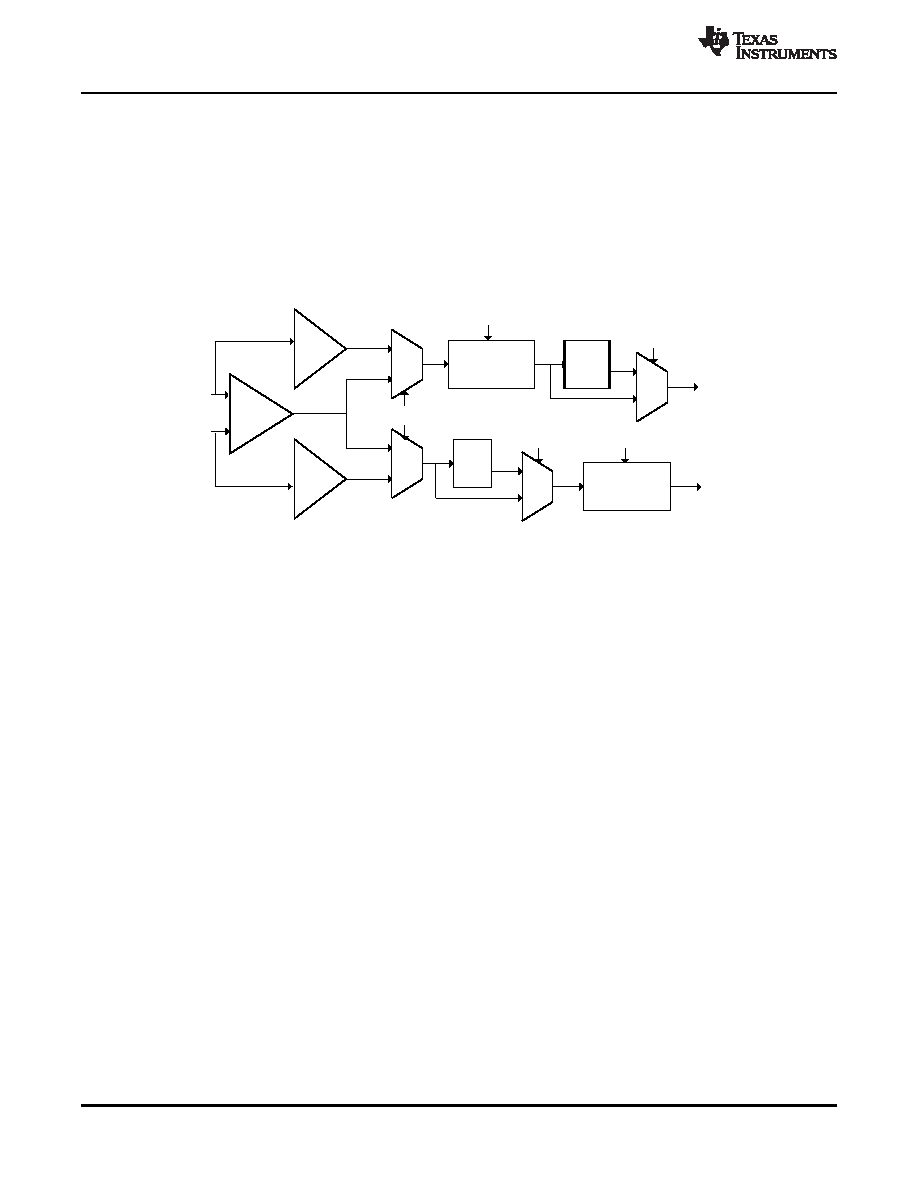

10.7.2 CLOCKING

The clock inputs are versatile. The AFE7225/7222 can be driven by a differential clock, a single-ended

clock or two independent single-ended clocks. Low voltage CMOS for single-ended and LVDS for

differential are supported clock levels. Since routing single-ended clocks on the printed circuit board is

different from system to system, it is possible to see some performance degradation in the data converters

if the clock becomes corrupted prior to entering the AFE7225/7222. This is less likely to occur if using a

differential clock routed on the board due to the common-mode noise rejection of the differential clock

receiver.

The full block diagram of the clocking to the ADC and DAC is shown below.

Figure 10-13. Clocking

Depending on the ADC input frequency and the target SNR of the receiver, it may be important to provide

a low jitter clock source to the AFE7225/7222. A good estimate for required clock jitter to achieve a certain

SNR can be found using SNR = 20*log10(2*pi*FINadc *JITTERtotal). The JITTERtotal is the rms

summation of the external clock jitter and the internal AFE7225/7222 RX ADC clocking aperture jitter,

specified in the timing characteristics table. A good target for the total jitter is a value that allows an SNR

that meets or exceeds the ADC SNR so that the clock source jitter will not degrade the SNR. Note that the

SNR is dependent on the analog input frequency and not the clock frequency.

When different rate clocks are required for the ADC and the DAC (for example, DAC_CLK is 2X rate of

ADC_CLK), it is strongly recommended that the input clock be at the higher of the two rates. Dividing the

high speed clock to derive the half rate clock always gives much lower jitter than using the PLL to multiply

the lower rate clock to derive the higher rate inside the chip. Use the PLL only when performance

requirements are relaxed and the additional jitter is tolerable (usually when the analog I/O frequencies are

low).

The equivalent circuit model of the differential buffer is shown below. Note that even with the single ended

buffer is enabled, the loading from the passive components in the differential buffer circuit (including the 2

pF differential cap, the two 5 kOhm resistors and the equivalent input load, Ceq are still present).

88

DIGITAL INTERFACE

Copyright 2011–2012, Texas Instruments Incorporated

相關PDF資料 |

PDF描述 |

|---|---|

| ECE-V1EA100NP | CAP ALUM 10UF 25V 20% SMD |

| 0210491116 | CABLE JUMPER 1.25MM .305M 39POS |

| UPM1J270MED1TD | CAP ALUM 27UF 63V 20% RADIAL |

| RNF-100-1-1/4-RD-SP | HEAT SHRINK TUBING |

| RNF-100-1-1/4-BU-SP | HEAT SHRINK TUBING |

相關代理商/技術參數 |

參數描述 |

|---|---|

| AFE7222IRGC25 | 功能描述:射頻前端 Dual 12B,65MSPS ADC RoHS:否 制造商:Skyworks Solutions, Inc. 類型: 工作頻率:2.4 GHz, 5 GHz 最大數據速率:54 Mbps 噪聲系數: 工作電源電壓:3.3 V 電源電流:180 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:QFN-32 |

| AFE7222IRGCR | 功能描述:射頻前端 Dual 12B,65MSPS ADC RoHS:否 制造商:Skyworks Solutions, Inc. 類型: 工作頻率:2.4 GHz, 5 GHz 最大數據速率:54 Mbps 噪聲系數: 工作電源電壓:3.3 V 電源電流:180 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:QFN-32 |

| AFE7222IRGCT | 功能描述:射頻前端 Dual 12B,65MSPS ADC RoHS:否 制造商:Skyworks Solutions, Inc. 類型: 工作頻率:2.4 GHz, 5 GHz 最大數據速率:54 Mbps 噪聲系數: 工作電源電壓:3.3 V 電源電流:180 mA 最大工作溫度:+ 85 C 安裝風格:SMD/SMT 封裝 / 箱體:QFN-32 |

| AFE7225 | 制造商:TI 制造商全稱:Texas Instruments 功能描述:Analog Front End Wideband Mixed-Signal Transceiver |

| AFE7225EVM | 功能描述:射頻開發工具 AFE7225 Eval Mod RoHS:否 制造商:Taiyo Yuden 產品:Wireless Modules 類型:Wireless Audio 工具用于評估:WYSAAVDX7 頻率: 工作電源電壓:3.4 V to 5.5 V |

發布緊急采購,3分鐘左右您將得到回復。